OneTouch

Complexity of Managing Inventory and Production

Organizations face daily complexity: lack of real-time stock visibility, manual inventory processes, and supplier coordination issues. Expired or lost products, production planning difficulties, and cost control challenges are compounded by traceability requirements and the risk of stock shortages or overstock, often with data fragmented across systems.

- Lack of real-time stock visibility

- Manual inventory processes

- Supplier coordination issues

- Expired or lost products

- Production planning difficulties

- Cost control challenges

- Traceability requirements

- Risk of stock shortages or overstock

- Data fragmentation across systems

Operational Cost of Poor Inventory Control

Typical pain points without unified inventory and traceability

Manual counts, poor visibility, and fragmented data drive stock-outs, waste, and production delays.

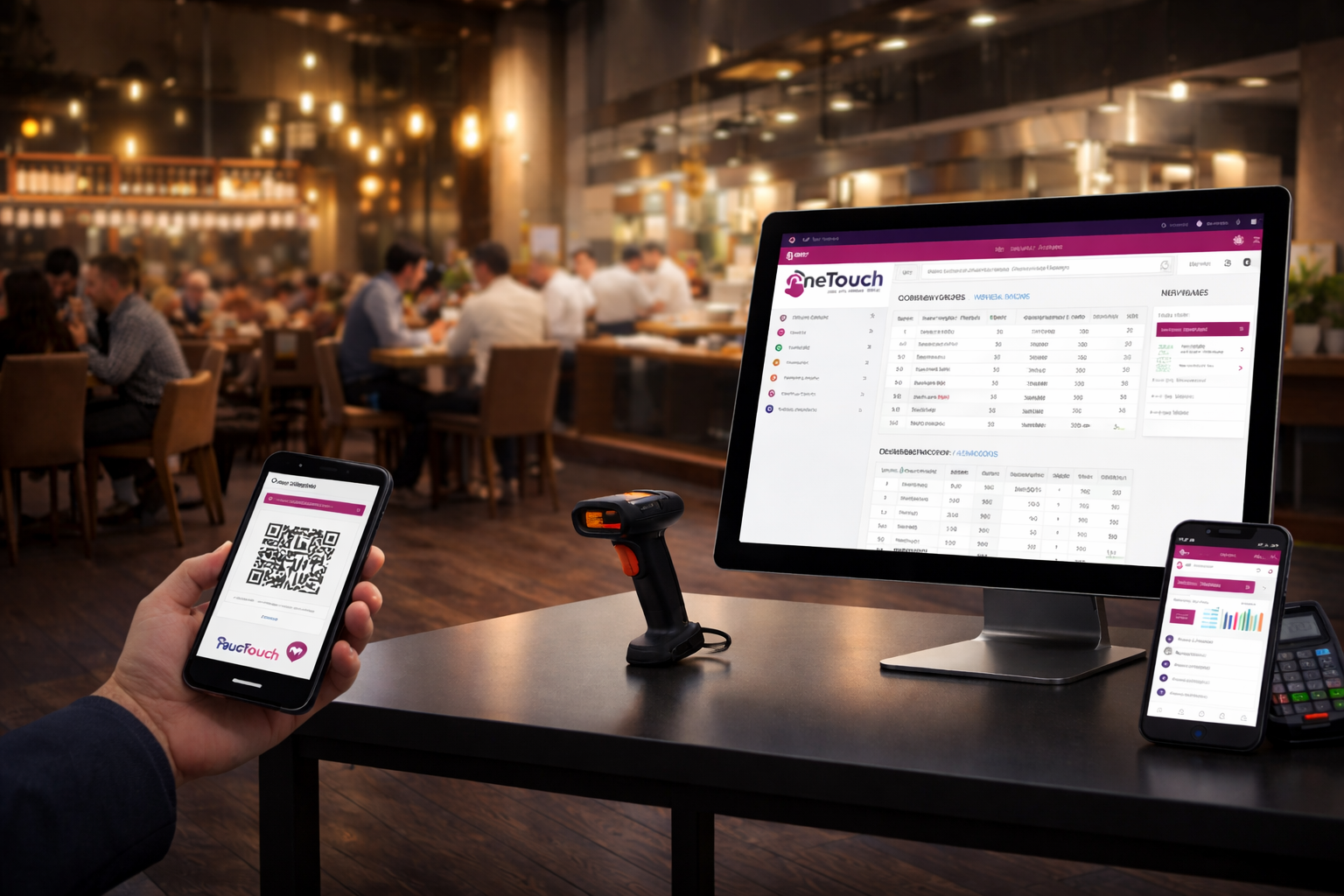

OneTouch — A Unified Platform for Operations Management

OneTouch centralizes procurement processes, inventory tracking, warehouse operations, production planning, supplier management, cost monitoring, and product lifecycle management with real-time operational visibility.

- Procurement processes

- Inventory tracking

- Warehouse operations

- Production planning

- Supplier management

- Cost monitoring

- Product lifecycle management

- Real-time operational visibility

Purchase orders by status (sample month)

Procurement and delivery monitoring improve supplier coordination.

Control Your Supply Chain

- Supplier database management

- Purchase requests and orders

- Price tracking

- Contract terms

- Delivery monitoring

- Invoice and payment tracking

- Raw material management

- Packaging management

Real-Time Stock Visibility

- Multi-warehouse management

- Stock movements tracking

- Reception workflows

- Transfers between depots

- Minimum and maximum stock alerts

- Expiration date monitoring

- Loss and waste tracking

- Inventory valuation

Plan and Execute Production Efficiently

- Manufacturing orders

- Bill of materials / recipes

- Resource planning

- Production scheduling

- Material consumption tracking

- Finished goods management

- Cost calculation

- Direct sales entry

Complete Traceability from Source to Delivery

- Batch and lot tracking

- Expiration date control (DLC)

- Quality control records

- Movement history

- Audit trails

- Regulatory compliance support

- Alerts for anomalies

Make Data-Driven Decisions

- Operational dashboards

- Cost of production analysis

- Stock valuation reports

- Profitability insights

- Performance indicators

- Forecasting support

- Real-time KPIs

Unit cost trend (sample product, €)

Cost monitoring supports production and procurement decisions.

Built for Complex Organizations

- Multi-site deployment

- Centralized administration

- Role-based permissions

- User management

- Custom workflows

- Integration capabilities

- Scalable architecture

Business Impact

Impact of OneTouch on Operations

Before vs after unified inventory, procurement, and traceability

Real-time stock, automated reorders, and full traceability reduce waste and improve on-time delivery.

Gain Full Control of Your Operations with OneTouch

Deploy a unified platform for inventory, procurement, and production management.